| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Piece/Pieces |

| Delivery Time: | 7 Days |

Basic Info

Model No.: DTII/TK/TK75

Roller Material: Seamless Roller Pipe,welded Roller Pipe

Rolelr Diameter: 89mm-195mm

Shaft: 20-100mm,

Belt Length: 400 Mm-2600mm

Standard: ISO, DIN, CEMA, GB

Roller Bearing: Roller Bearing 22200 22300 Series

Application: Coal Mining, Cement Plant, Power Plant

Additional Info

Packaging: 1)Neutral package & wooden package 2)Carton package+pallet 3)Wooden package+pallet 4)As customer request

Productivity: 50000 Pieces/day

Brand: XKTE/OEM

Transportation: Ocean,Land,Air

Place of Origin: Shandong, China

Supply Ability: 50000 Pieces/Day

Certificate: ISO9001

Port: Qingdao,Shenzhen,Guangzhou

Product Description

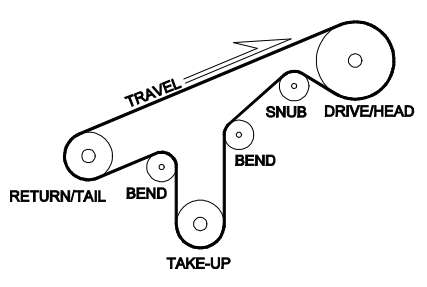

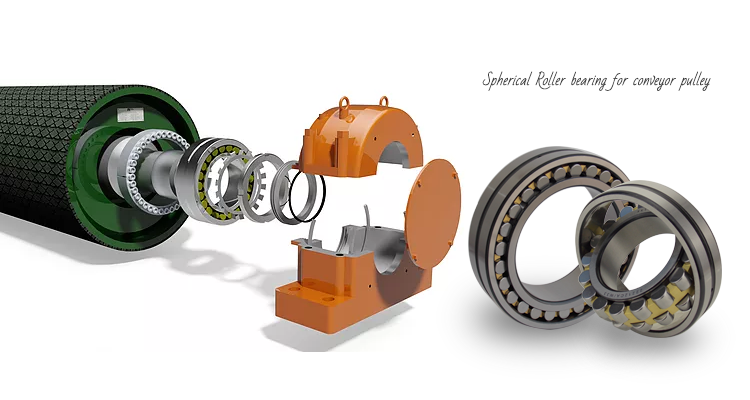

Mining And Minerals Industries Conveyor,working 24/7 to convey bulk materials in coal mining, ore mining, hard quarry and related materials. Conveyor pulleys play an essential role in the performance and reliability of belt conveyor systems worldwide. It is because of this essential role that pulley selection becomes a critical process in keeping equipment up and running. Spherical roller bearing are available with heavy duty pulleys and cages that are suitable for extreme demand harsh applications such as vibratory screens. Mining Conveyor Machine, and mining bulk conveyor pulley. self-aligning ball bearing for light duty pulleys. XKTE specialize in producing reinforced ball beairng for conveyor idler and roller beairng for drum pulley.

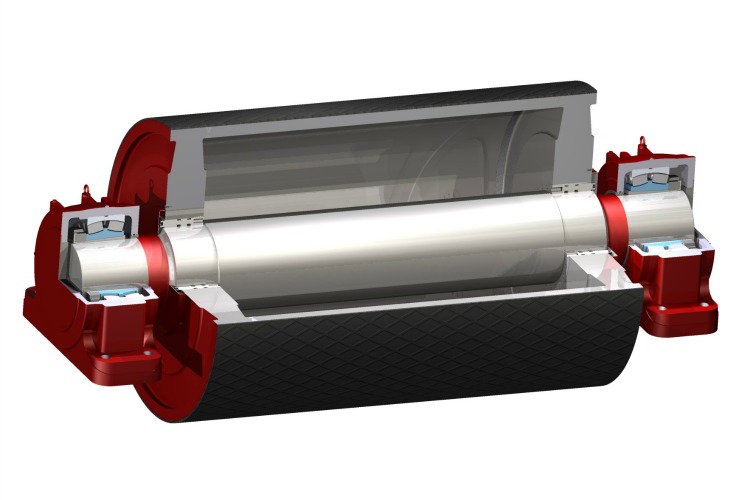

1. Drum or Shell:

The drum is the portion of the pulley in direct contact with the belt. The shell is fabricated from either a rolled sheet of steel or from hollow steel tubing.

Diaphragm Plates: The diaphragm or end plates of a pulley are circular discs which are fabricated from thick steel plate and which are welded into the shell at each end, to strengthen the drum.

The end plates are bored in their centre to accommodate the pulley shaft and the hubs for the pulley locking elements.

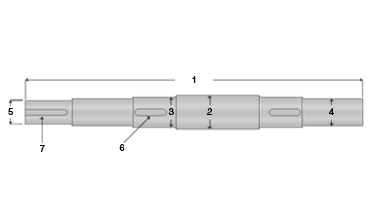

Shaft:The shaft is designed to accommodate all the applied forces from the belt and / or the drive unit, with minimum deflection. The shaft is located and locked to the hubs of the end discs by means of a locking elements. The shaft and hence pulley shafts are often stepped.

Locking Elements:These are high-precision manufactured items which are fitted over the shaft and into the pulley hubs. The locking elements attach the pulley firmly to the shaft via the end plates.

Hubs:The hubs are fabricated and machined housings which are welded into the end plates.

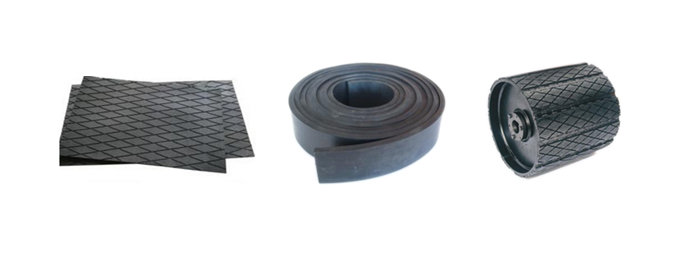

Lagging: It is sometimes necessary or desirable to improve the friction between the conveyor belt and the pulley in order to improve the torque that can be transmitted through a drive pulley. Improved traction over a pulley also assists with the training of the belt. In such cases pulley drum surfaces are `lagged` or covered in a rubberized material.

Bearing: Bearings used for conveyor pulleys are generally spherical roller bearings, chosen for their radial and axial load supporting characteristics. The bearings are self-aligning relative to their raceways, which means that the bearings can be 'misaligned' relative to the shaft and plummer blocks, to a certain degree. In practical terms this implies that the bending of the shaft under loaded conditions as well as minor misalignment of the pulley support structure, can be accommodated by the bearing.

Other Main Products for conveyor pulley:

Spherical roller bearing

Series 22200.., 22300.., 23000.., 23100.., 23200.., 23900.. 24000.., 24100.., M/MB/CA/CC/W33

Models

Old Models

Bore(d)

Outer Diameter(D)

Thickness

Weight

22210

3510

50

90

23

0.87

22211

3511

55

100

25

0.88

22212

3512

60

110

28

1.22

22213

3513

65

120

31

1.63

22214

3514

70

125

31

1.66

22215

3515

75

130

31

1.75

22216

3516

80

140

33

2.2

22217

3517

85

150

36

2.8

22218

3518

90

160

40

4

22219

3519

95

170

43

4.2

22220

3520

100

180

46

5

22222

3522

110

200

53

7.4

22224

3524

120

215

58

9.2

22226

3526

130

230

64

11.2

22228

3528

140

250

68

14.5

22230

3530

150

270

73

18.5

22232

3532

160

290

80

22.2

22234

3534

170

310

86

29

22236

3536

180

320

86

30

22238

3538

190

340

92

35.3

22240

3540

200

360

98

44.7

22244

3544

200

400

108

61.5

22248

3548

240

440

120

61.7

22256

3556

280

500

130

115

22307

3607

35

80

31

0.75

22308

3608

40

90

33

1.03

22309

3609

45

100

36

1.4

22310

3610

50

110

40

1.9

22311

3611

55

120

43

2.4

22312

3612

60

130

46

3

22313

3613

65

140

48

3.6

22314

3614

70

150

51

4.4

22315

3615

75

160

55

5.4

22316

3616

80

170

58

6.4

22317

3617

85

180

60

7.4

22318

3618

90

190

64

8.8

22319

3619

95

200

67

10.3

22320

3620

100

215

73

13

22322

3622

110

240

80

18.1

22324

3624

120

260

86

22

22326

3626

130

280

93

29

22328

3628

140

300

102

36

22330

3630

150

320

108

43

22332

3632

160

340

114

51

22334

3634

170

360

120

60

22336

3636

180

380

126

70

22338

3638

190

400

132

81

22340

3640

200

420

138

94

22344

3644

220

460

145

119

22348

3648

240

500

155

153

self-aligning ball bearing

Models

Bore(d)

Outer Diameter(D)

Thickness

Weight

1308

40

90

23

0.715

1309

45

100

25

0.957

1310

50

110

27

1.21

1311

55

120

29

1.58

1312

60

130

31

1.96

1313

65

140

33

2.45

1314

70

150

35

2.99

1315

75

160

37

3.56

1316

80

170

39

4.18

APPLICATION:

Spherical roller bearings and self-aligning ball bearings are available with heavy duty rollers and cages that are suitable for extreme demand harsh applications such as vibratory screens. Mining Conveyor Machine, and mining bulk conveyor pulley. Bend Pulley,Driving Pulley, Head Pulley, Snub Pulley, Tail Pulley, Take Up Pulley etc. In this sort of aggressive operational environment, the spherical roller bearing is the only type that delivers acceptable service life. generally have a longer life span than other bearing types.

Special: XKTE - Ball Bearings and Rolling Bearings in Conveyor Technology

XKTE is the specialist in rolling bearing technology for the mechanical application of continuous conveyors.

Whether bulk or general cargo conveyor, we have the right solutions for your requirements. Application-optimized rolling bearings from XKTE master all challenges: Heavily different temperatures, moisture, dust, dirt, as well as noise and vibration reduction.

About US:

Shandong Xinkaite Bearing Co., Ltd. is a professional belt conveyor roller bearing manufacturer enterprise, specialized in manufacturing bearings for the bulk material handling industry and supply all kinds of conveyor idler components. our bearings are being used in multiple applications including: mining machinery, carrying idlers and reverse rollers as well as drum pulley. Our factory is located in Yandian of Liaocheng in mainland China, covered an area of 18,000 square meters, registered trademarks "XKTE".

And there are many long-term fixed partners of ours within the areas centered by conveyor roller bearing industry. With our company`s gradually growing, from the rough to the bearing, we set up a one-stop production line, with 50000 pieces produced every day on our automated production lines. all products are manufactured according to GB standards or in compliance with your specific requirements.

Our Service:

1. Volume production and large Inventories, stable quality

2. OEM is supported

3. Small order accept

4. Various Brands

5. Wide Array of Applications

6. Fast delivery

7. Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

Packing

© 2019 CHINA WAY. All Rights Reserved. Shandong Xinkaite Bearing Co., Ltd., Inc. All rights reserved. site map. sitemap.html