| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 7 Days |

Basic Info

Model No.: TD75 DTII

Material: Steel

Application: Chemical Industry, Mining Transport, Power Plant

Structure: Three Chain Roller

Bearing Type: KA Retainer Bearing

Type: Impact Idler

Additional Info

Packaging: 1)Neutral package & wooden package 2)Carton package+pallet 3)Wooden package+pallet 4)As customer request

Productivity: 50000 Pieces/day

Brand: XKTE/OEM

Transportation: Ocean,Land,Air,Express

Place of Origin: Shandong,China

Supply Ability: 50000 Pieces/Day

Certificate: ISO9001:2015

Port: Qingdao,Guangzhou,Shenzhen

Product Description

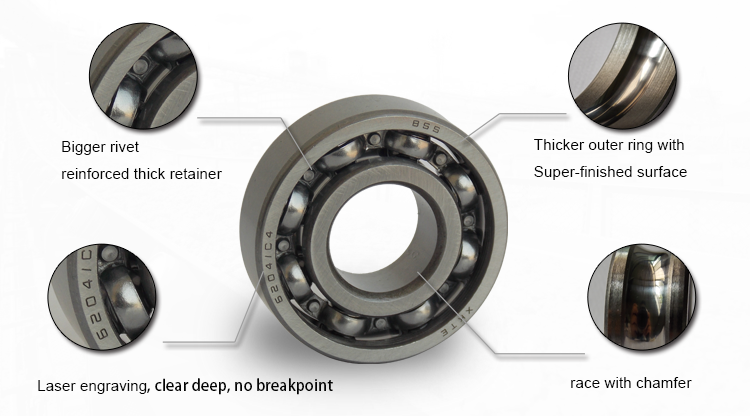

We provide spare parts for belt conveyor Equipment. Impact idler is also called buffer roller or feeding roller. Side by side, there are rubber rings assembled on steel roller, and impact idler frames are reinforced to reduce bending and withstand heavy bulk material loads, to absorb the weight and impact of material falling onto the conveyor belt. The most important parts of idler is bearing, we producing unique deep groove ball bearing with good anti seizeing performance. reinforced retainer, bigger rivet, thick inner and outer rings.

Impact idler rollers are located at loading and transfer points, are a special version of troughing idlers, providing a roll with cushioning rubber discs to lessen the belt damage due to impact from materials being loaded onto the belt. The frame is additionally reinforced to increase ridgidity.

BENEFITS:

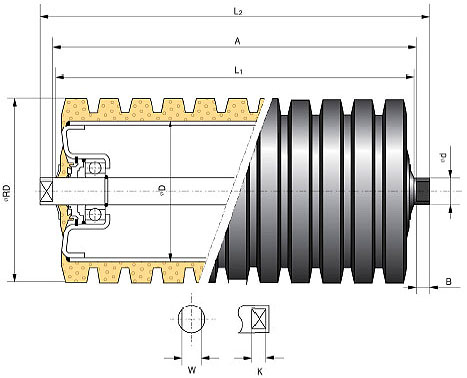

Conveyor idler Roller Structure

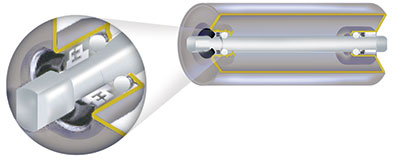

1. Conveyor Idler Tube or shell. The Shells are made from steel tube with close tolerance ensuring smooth, Shock free and eccentricity free running with minimum dimensional run out, smallest rotating weight of rollers requires low horse power, thereby conserving power and energy due to lowest possible dynamic friction.

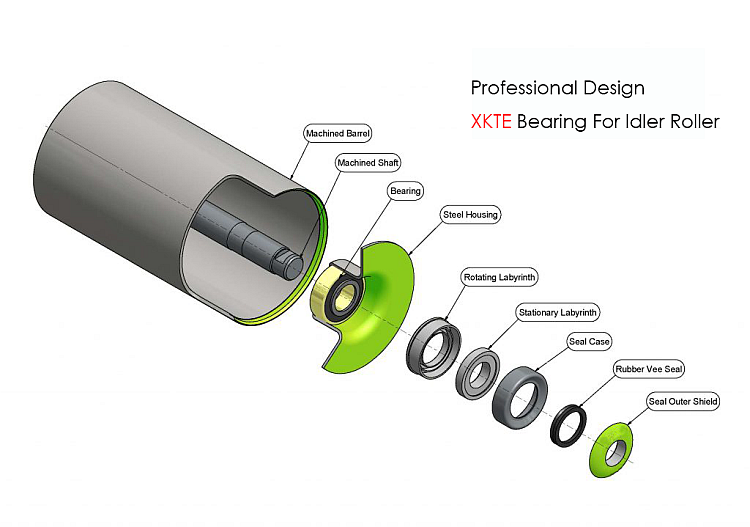

2. Seals should be multi labyrinth type to prevent ingress of dirt, air and moisture. The outer seal should be corrosion resistant.

3. Bearing housing are formed from strip steel deep pressed in automatic presses machine, this tolerance allowing a perfect match between the bearing and the relevant parts of the sealing.

4. Bearing. Large clearance C3/C4 serials deep groove ball bearings, reinforced cage with big rivet, thick inner ring and outer ring. usually use double sealed structure to improve the water and dust proof ability.

Diameter of idler mm

Length of idler(tube)mm

Bearings

89

190.200.230.240.280.305.315.375.380.455.465.600.750.950.1150

6204

108

190.200.240.250.305.315.375.380.455.465.525.600.700.750.800.950.1150.1400

6205

133

305.350.375.380.455.465.525.530.600.700.790.800.950.1150.1400.1600

6305

159

375.380.455.465.525.630.600.640.670.700.750.790.800.900.950.1050.1120.1150.1400.1600

6306 6308

193.7

600.640.750.800.900.950.1050.1120

6308

6310

217

600.640.1050.1120

6310

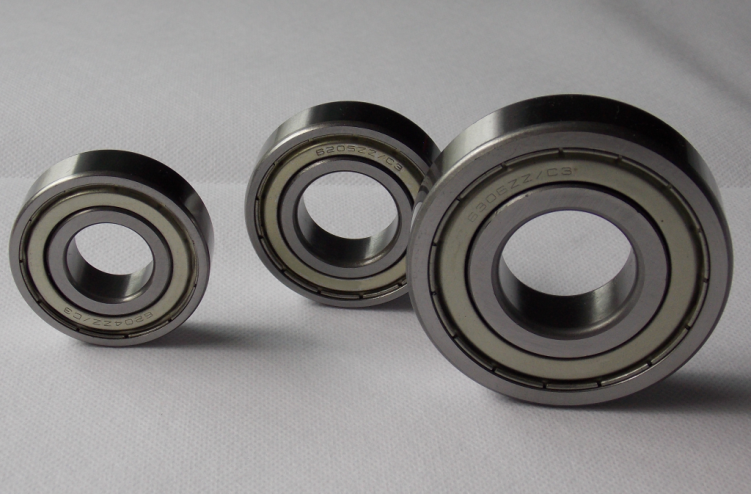

Types of Ball bearing for belt impact idler:

6200/6300 series deep groove ball bearing

6200/6300 series is well suited for low to heavy radial loads and can be configured for various application speeds and running precision requirements. Reinforced iron Retainer, Super-finished deep groove, smooth race, thicker inner and outer ring.

|

6200/6300 Series Deep Groove Ball Bearing |

|||||||

|

Model |

Bore Size(mm) |

Outer Diameter(mm) |

High(mm) |

Weight(kg) |

ball no. |

Cr(kN) |

Cor(kN) |

|

6204 |

20 |

47 |

14 |

0.106 |

8 |

12.8 |

6.65 |

|

6205 |

25 |

52 |

15 |

0.128 |

9 |

14 |

7.85 |

|

6305 |

25 |

62 |

17 |

0.232 |

7 |

20.6 |

11.3 |

|

6306 |

30 |

72 |

19 |

0.346 |

8 |

26.7 |

15 |

|

6307 |

35 |

80 |

21 |

0.457 |

8 |

33.4 |

19.3 |

|

6308 |

40 |

90 |

23 |

0.639 |

8 |

40.8 |

24 |

|

6309 |

45 |

100 |

25 |

0.837 |

8 |

52.8 |

31.8 |

|

6310 |

50 |

110 |

27 |

1.082 |

8 |

61.8 |

38 |

|

Material Chrome Steel GCr15 |

|||||||

Types:

Nylon cage bearing: 6204KA---6308KA 6204KA/C3---6308KA/C3 6204KA/C4---6308KA/C4

Rubber Sealed bearing: 6204-2RS/RS---6310-2RS 6204-2RZ---6310-2RZ 180204---180308

Shielded Ball Bearing: 60204---60310 6204KA-Z---6308KA-Z 6204TN-Z---6308TN-Z 6204ZZ---6310ZZ

Feature of Ball Bearing

Our Service:

1. Volume production and large Inventories, stable quality

2. OEM is supported

3. Small order accept

4. Various Brands

5. Wide Array of Applications

6. Fast delivery

7. Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

About US:

Shandong Xinkaite Bearing Co., Ltd. is a professional belt conveyor roller bearing manufacturer enterprise, specialized in manufacturing bearings and conveyor components for the bulk material handling industry. our bearings are being used in multiple applications including: mining machinery, carrying idlers and reverse rollers as well as drum pulley. Our factory is located in Yandian of Liaocheng in mainland China, covered an area of 18,000 square meters, registered trademarks "XKTE".

To be the first class, to do the best quality, to make users satisfied, to ensure customers relieved, are our enterprise purposes. Welcome bearing dealers` and conveyor idler manufacturers contact from all over the world, and become our partner.

© 2019 CHINA WAY. All Rights Reserved. Shandong Xinkaite Bearing Co., Ltd., Inc. All rights reserved. site map. sitemap.html