| Payment Type: | L/C,T/T,Paypal,Western Union |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 100 Piece/Pieces |

| Delivery Time: | 5 Days |

Basic Info

Model No.: Bearing 6309 C4

Aligning: Non-Aligning Bearing

Separated: Unseparated

Rows Number: Single

Load Direction: Radial Bearing

Material: Bearing Steel, Chrome Steel GCr15

Inner Diameter: 45mm

Outer Diameter: 100mm

Width: 25MM

Weight: 0.837kg

Precision Rating: ABEC-1 (P0), ABEC-3 (P6),ABEC-5(P5),ABEC-7(P4)

Cage: Iron

Application: Conveyor Idler/Industrial Machine

Seals Type: Open Type

Additional Info

Packaging: 1)Neutral package & wooden package 2)Carton package+pallet 3)Wooden package+pallet 4)As customer request

Productivity: 50000 Pieces/day

Brand: XKTE

Transportation: Ocean,Land,Air

Place of Origin: Shandong,China

Supply Ability: 50000 Pieces/Day

Certificate: ISO9001:2015

HS Code: 8482102000

Port: Qingdao,Shenzhen,Guangzhou

Product Description

Bulk Conveyor Ball Bearing 6309 C4, big clearance so that this bearing can be allowed bending deformation and installation error of roller shaft. All of our ball bearing use thick inner/outer rings and deepen raceway, big rivet, especially used in dusty hostile environment. XKTE Professional commitment bearing for mining belt conveyor more than ten years.

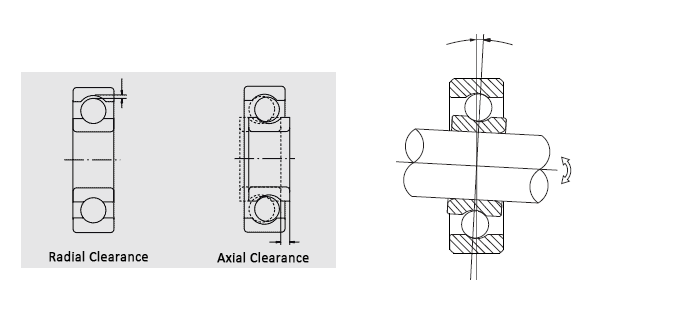

Clearance:

Deep groove ball bearings have internal clearance. This provides the bearing room for expansion between the bearing races and will add a small amount of play between the two rings. Large clearance C3/C4 usually used in harsh environment. with good anti-seize performance used in particularly harsh environment.

Tolerances

The standard version of our single-row deep groove ball bearings has the tolerance class P0

(designs with tighter tolerances available upon request)

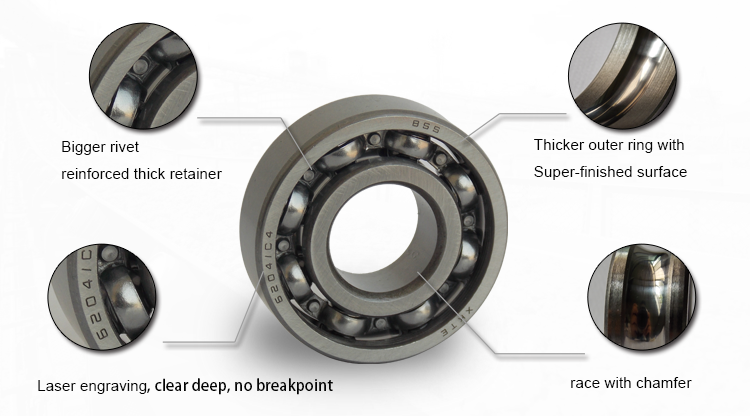

Design Characteristic:

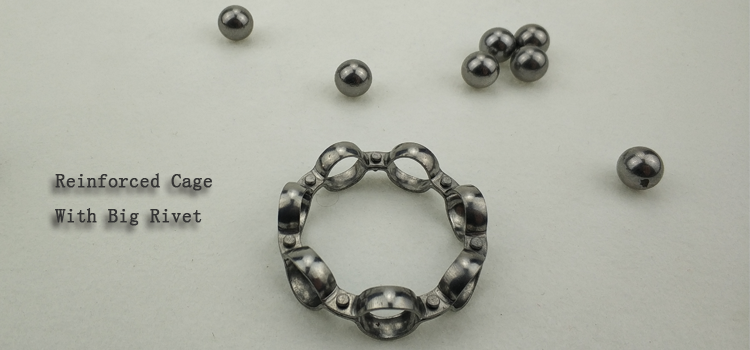

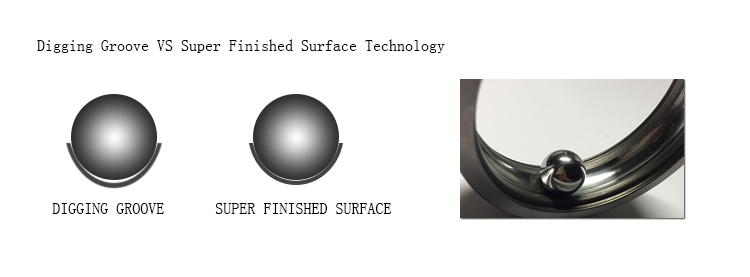

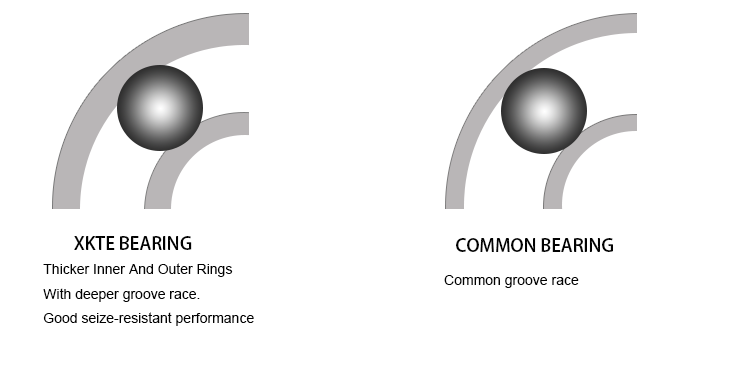

Our open type deep groove ball bearings use unique design steel cage, The inner/outer rings and Retainer(cage) are thicker compare with the Common bearings, stronger rivet, which consist more reliable structure. strong impact and heavy load with Grinding groove and super finished surface technology. to offer the long life under extreme harsh environment.

Details Of Thick Cage

Super Finished Surface Technology

Dimensions such as the outer and inner diameters and the width are ground to micrometer (one-thousandth of a millimeter) precision, as is the groove, a key internal structure formed between the inner and outer rings in which balls run.

Thicker Inner & Outer Ring

The ring is the main part and the important part of the idler roller bearing. Best idler roller bearing has deep groove ball, and large clearance. But deep groove doesn`t mean to dig the channel with a simple way of enlarge the steel ball. The thickness of the bearing is certain, so to get the ball big and the groove deep will shorten service life. Our XKTE bearing uses way of thickening ring to get the standard of deep groove and large clearance, improves the anti-stuck performance, and effectively increases the service life.

Other Main Products for idler:

6200/6300 series deep groove ball bearing

6200/6300 series ball bearings are well suited for low to heavy radial loads and can be configured for various application speeds and running precision requirements. Reinforced iron Retainer, Super-finished deep groove, smooth race, thicker inner and outer ring.

|

6200/6300 Series Deep Groove Ball Bearing |

|||||||

|

Model |

Bore Size(mm) |

Outer Diameter(mm) |

High(mm) |

Weight(kg) |

ball no. |

Cr(kN) |

Cor(kN) |

|

6204 |

20 |

47 |

14 |

0.106 |

8 |

12.8 |

6.65 |

|

6205 |

25 |

52 |

15 |

0.128 |

9 |

14 |

7.85 |

|

6305 |

25 |

62 |

17 |

0.232 |

7 |

20.6 |

11.3 |

|

6306 |

30 |

72 |

19 |

0.346 |

8 |

26.7 |

15 |

|

6307 |

35 |

80 |

21 |

0.457 |

8 |

33.4 |

19.3 |

|

6308 |

40 |

90 |

23 |

0.639 |

8 |

40.8 |

24 |

|

6309 |

45 |

100 |

25 |

0.837 |

8 |

52.8 |

31.8 |

|

6310 |

50 |

110 |

27 |

1.082 |

8 |

61.8 |

38 |

|

Material Chrome Steel GCr15 |

|||||||

We will consider all the applicable variables in your application, such as extreme temperature variation, dust and dirt, as well as noise and vibration requirements.

Professional Conveyor Bearing Manufacturer for Conveyor Idler Roller, Impact idler, Troughing idler and pulley bearing for bend pulley, drive pulley etc.

About US:

Shandong Xinkaite Bearing Co., Ltd. is a professional belt conveyor roller bearing manufacturer enterprise, specialized in manufacturing bearings for the bulk material handling industry. our bearings are being used in multiple applications including: mining machinery, carrying idlers and reverse rollers as well as drum pulley. Our factory is located in Yandian of Liaocheng in mainland China, covered an area of 18,000 square meters, registered trademarks "XKTE".

And there are many long-term fixed partners of ours within the areas centered by conveyor roller bearing industry. With our company`s gradually growing, from the rough to the bearing, we set up a one-stop production line, with 50000 pieces produced every day on our automated production lines. all products are manufactured according to GB standards or in compliance with your specific requirements.

Our Service:

1. Volume production and large Inventories, stable quality

2. OEM is supported

3. Small order accept

4. Various Brands

5. Wide Array of Applications

6. Fast delivery

7. Our company insists on the "quality first, credit first" business ideas and our product specification is well-founded. We have a good reputation in the international market by our perfect service and sufficient supply.

Packing

© 2019 CHINA WAY. All Rights Reserved. Shandong Xinkaite Bearing Co., Ltd., Inc. All rights reserved. site map. sitemap.html